Services

TOBTOM Mixing Systems designs low-pressure injection equipment and offers production,

RIM technology, sales, and service.

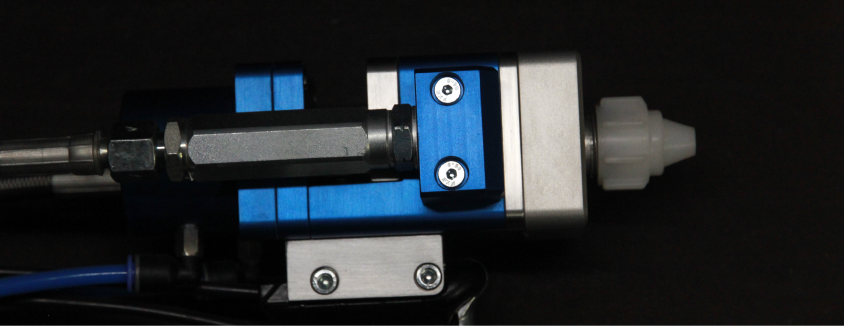

Dispensers

Design and Manufacturing

We design and build low-pressure injection systems, tailored to the specific needs of our clients

Production

Production Types:

Single-unit

Serial

Prototyping

Additional services:

Working with client-supplied molds

Sealing with electro-insulating resins for electrical and electronic components (coils, transformers, capacitors)

RIM Technology

We manufacture castings using Reactive Injection Moulding (RIM) technology.

Thanks to this method, it is possible to produce larger and lighter parts with more complex shapes than traditional injection moulding.

This method ensures excellent repeatability and superior surface quality.

The forming process is distinguished by lower production costs. The moulds are made from less expensive materials than steel, and the low viscosity of the prepolymer allows forming at 20–40°C and 3–10 bar, reducing energy consumption.

What is RIM?

Reaction Injection Moulding (RIM) is a low-pressure process for producing molded plastic parts. Polyol and isocyanate, along with optional additives, are first mixed and then injected as a reactive mass at 4–6 bar into a mould made of aluminium, polymer concrete, or ureol. The crosslinking reaction hardens the material inside the mould. RIM technology allows the production of both soft and hard polyurethane components, with various Shore hardness levels, including integral foam or elastomeric parts.

Compared to conventional injection processes, RIM features lower viscosity, which enables longer flow paths within the same wall thickness — making it ideal for thin-walled, large, and complex parts.

In small-batch production, moulds are mainly made from polymer concrete (PB).

Due to the high surface durability of such moulds, larger quantities can be produced using low-pressure RIM. In many cases, RIM is a suitable alternative to conventional spray moulding processes.

Component sales

We supply consumable parts such as static and dynamic mixers.

Static and dynamic mixers

Components for plastic production

Technical support in material selection

Service and Technical Support

Spare and consumable parts supply

Machine operation training

Warranty and post-warranty service

Our machines meet the requirements of the following European directives and standards:

Directives:

Machinery Directive 2006/42/EC

Low Voltage Directive (LVD) 2014/35/EU

Electromagnetic Compatibility Directive (EMC) 2014/30/EU

Harmonized Standards:

PN-EN ISO 12100:2012

PN-EN ISO 13849-1:2016-02

PN-EN ISO 13850:2016-03

PN-EN 60204-1:2018

PN-EN 61310-3:2010

PN-EN 1005-1+A1:2010

PN-EN 14120:2016-03